SERVO MOTOR MAINTENANCE

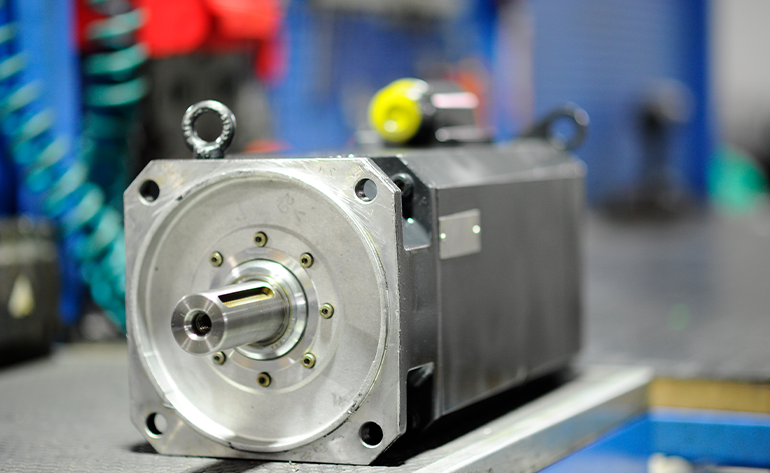

AC Servo, DC Servo and Stepper motors have the same structure and operation logic. They differ in terms of the structure of the driver and control circuit. AC Servo motors; Advances in semiconductor technology, technological developments in electronics and communication protocols have made AC Servo motor controls popular due to their more precise positioning and fast reaction.

Servo System; Servo Controller (Driver) - Servo Motor - Reverse communication system (Encoder) consists of 3 main products.

Servo Controller selection should be made according to the motor characteristics selected according to the mechanical load and motion system (Linear or Circular). After selecting the Servo motor and Servo Controller, the Feedback System (Encoder) that will form the combination between the Servo motor and the Servo Controller should be selected according to the driver characteristics.

Thanks to the serial communication protocols between the feedback and the servo controller, positioning, speed, temperature, etc. at the level of microseconds. exchange of information can be achieved easily.

In addition, thanks to the Digital software used in the latest system feedback (Encoder) systems, all information about the Servo Motor under the "Electronic Name Plate" is written by the manufacturer.

Motors that detect the error of any mechanism and report feedback are called servo motors. It works with brushless DC motor logic. It is used in mechanical, electronic, hydraulic (operating in oily environment) and pneumatic (working in contact with air) fields. Servo motor includes AC, DC, VE Stepper motors. It also contains the driver and control circuit. Servo motors are used in many industries.

Siemens, Fanuc, Kuka, Kollmorgen, ABB, Br Automation, Yaskawa, Mitsubishi, Tamagawa and many brands of servo motors are available.

Servo motors change according to the working conditions and conditions after a certain period of time; Problems such as noise operation, encoder error, mechanical problems, bearing failures, inability to adjust commutation angles after maintenance may cause problems in machine operation. All these problems are called Servo Motor Failure. It is to remove the engine from the bench and send it to an authorized service without any action on the engine in order to correct the engine fault correctly.

Si-mut Teknik is a service that helps all brands of servo motors.

There are many servo motor service centers. Every action on the engine is very important. Repairs should be made by going through the process stages that require sensitive workmanship and experience. Incorrect actions to be applied to the engine will cause you to lose time and cost, the benches to come to a standstill and even damage the benches. Your choice of company is very important in this respect.

SI-MUT,

With more than 20 years of work experience and trained technicians, it has made a difference in the sector with its workmanship. Bursa/Nilüfer and İstanbul/Tuzla are two service centers.Both branches are working with the same quality. To defective motors sent to us;

*First of all, pre-registration is taken from the specially produced 'engine tracking' program belonging to Si-mut company.

*Preliminary information is received by the sales support team about the servo motor failure and the working environment of the servo motor with the customer.

*Failure diagnosis report is prepared quickly by our trained technicians and test equipment (UTE 2000 etc.) available only in Si-mut company.

*Sales support team sticks to this diagnostic report and provides detailed information about engine failure to the customer and offers an offer for engine repair cost.

*According to our customers' offer evaluation; repair of the servo motor can be approved or the return of the servo motor can be requested.

*Except in exceptional cases, no fault detection fee will be charged from the servo motors to be returned.

*All necessary operations are carried out on the approved motors, the test phase is performed again after the repair, the servo motor is cleaned and painted and made ready for shipment.

*No spare part replacement or operation that is not required for every engine to be repaired will not be made and will not be reflected in the offer.

*The material that is the subject of the offer is guaranteed for 6 months from the date of delivery against the faults caused by our company. Warranty conditions apply to engines under warranty. Errors caused by user error (impact, water entering the engine, etc.) costs including labor and parts are borne by the customer.